Full light power

Whether in vehicles, for room lighting, floodlighting or medical products: LED applications have gained increasing importance over the past years. Along with low power consumption and a long lifetime, it is the good luminous efficiency, flexible design possibilities and above all the innovative controllability that have boosted this technology. With the continuous further development of the lamps, printed circuit boards now also play a role in LED products that extends far beyond their original function as a carrier of electronic components. “In modern LED applications, the printed circuit board takes on ever more and more advanced functions. That is why printed circuit board and LED manufacturers need to collaborate intensively to meet requirements such as optimal heat dissipation or special reflective properties,” explains Ferdinand Lutschounig, Product Manager at AT&S. As a result, modern LED printed circuit boards allow additional functionalities such as the optimal dissipation of waste heat, specific reflective properties for high light output or the best possible utilization of the available space.

Optimal heat dissipation

In LED lamps heat is dissipated via the printed circuit board. To this end, the basic material of printed circuit board, a dielectric (which is an insulating material) with very moderate thermal conductivity values and, on the other hand, copper with better thermal conductivity are available. So far, mechanically drilled thermal vias were used to dissipate heat in various variants and simple embodiments of the metal core circuit board in use and met the requirements sufficiently. In the future, increasingly highly complex structures and combinations of existing and new technologies will be needed in order to dissipate larger amounts of heat efficiently.

Additional reflective properties

In order to achieve maximum light output, different surface coatings and materials are employed. “It is, for example possible that the solder resist also has reflective properties, thus helping the LED application to achieve the best possible light output,” says Lutschounig. “Appropriate solder resists are available for this purpose, featuring the highs reflective properties while at the same time providing high color stability.” The challenge is that the lacquers used must also fulfill all previous functionalities in addition to the new properties.

In this context, it is also possible to use a highly reflective basic material for the printed circuit board to be able to meet even higher reflective property requirements. One example of this is the combination of the printed circuit board basic material FR4 (a compound of epoxy and woven fiberglass cloth) and aluminum with a special, high-quality coating for LED ceiling lights.

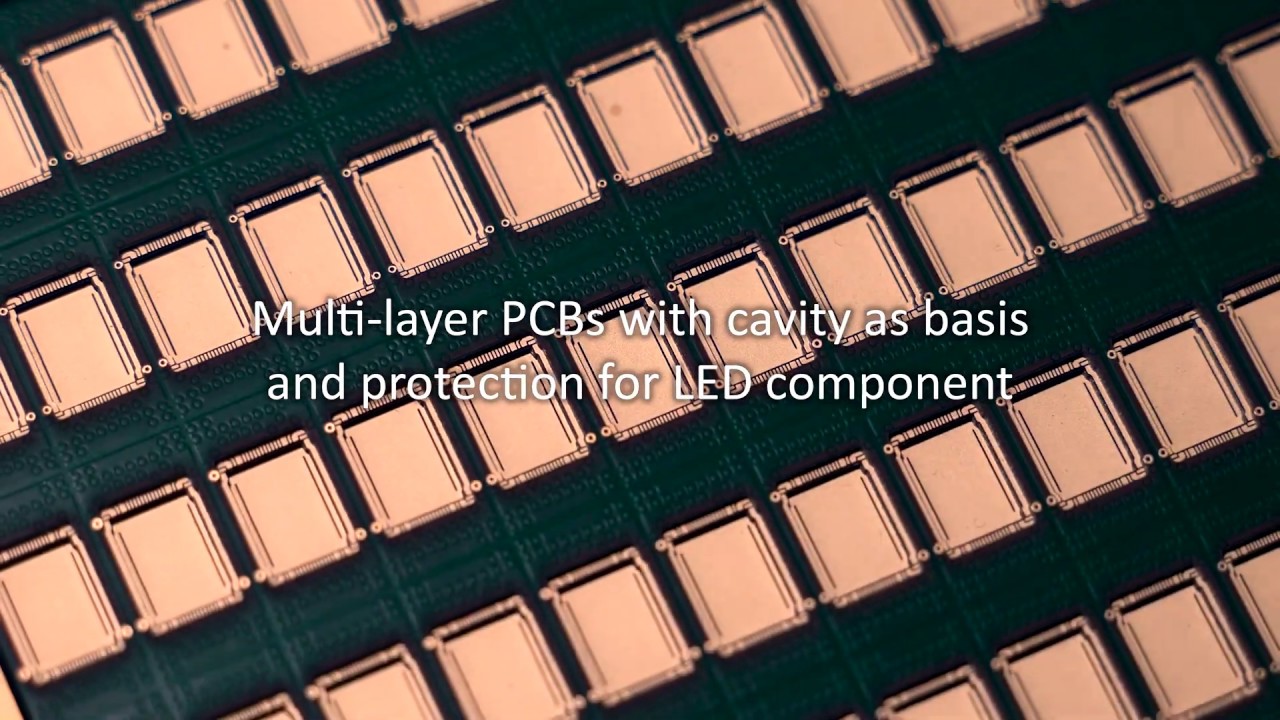

Additional functionality through individual design

Special designs and structures enable printed circuit boards to fulfill additional functions. If, for example, several cavities are integrated into a multilayer printed circuit board, a number of benefits can be realized: for instance, optimal heat dissipation becomes possible through the shortest possible path from the penultimate to the last layout layer and the use of copper in the form of microvias for heat dissipation. In addition, component installation on a contact surface (bond pad) on an inner layer allows for protection of the bond wires from external influences, and the cavity for the installation of the LED component simultaneously serves as a frame for potting, if required.

“However, these benefits can only be realized if printed circuit board, LED and light module manufacturers already cooperate during an early development phase,” says Ferdinand Lutschounig. Because: “This way, the respective expertise from different areas can influence the design of the components, of the printed circuit boards and of the finished product.”

分享文章: